The integration of electrospinning and 3D printing is revolutionizing next-generation stent development. These cutting-edge technologies enable precise engineering, personalized customization, and advanced therapeutic capabilities. Hybrid stents, combining both techniques, offer enhanced drug delivery, smart monitoring, and bioresorbable options, paving the way for improved patient outcomes and transformative advancements in cardiovascular care.

Introduction:

The field of medical technology is witnessing unprecedented advancements, particularly in the development of next-generation stents. Stents are crucial medical devices used to treat various cardiovascular conditions by restoring blood flow in narrowed or blocked blood vessels. Two groundbreaking technologies, electrospinning and 3D printing, have emerged as frontrunners in revolutionizing stent design and manufacturing. This detailed exploration delves into the intricacies of electrospinning, 3D printing, their synergistic applications in stent development, and the transformative impact on patient care.

Electrospinning: Precision Engineering at the Nanoscale

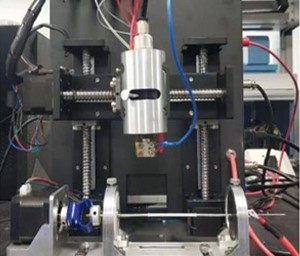

Electrospinning stands out as a remarkable technique for creating nanofibers with unparalleled precision and versatility. At its core, electrospinning involves the use of a high-voltage electrical field to draw ultra-fine fibers from a polymer solution. These nanofibers possess unique properties such as high surface area-to-volume ratio, mechanical flexibility, and excellent biocompatibility, making them ideal for biomedical applications.

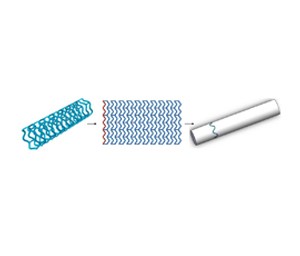

In the context of stents, electrospinning facilitates the fabrication of intricate scaffold-like structures that closely mimic the properties of natural blood vessels. The nanoscale architecture of electrospun fibers allows for precise control over mechanical strength, elasticity, and drug-loading capacities. This level of customization is pivotal in designing stents that seamlessly integrate into the vascular system, reduce the risk of complications such as restenosis, and enhance long-term efficacy.

Moreover, electrospinning enables the incorporation of therapeutic agents, such as drugs or growth factors, directly into the stent material. This capability transforms stents into dynamic platforms for targeted drug delivery, ensuring localized treatment and minimizing systemic side effects. The controlled release of drugs from electrospun stents can prevent inflammation, promote tissue regeneration, and improve overall patient outcomes.

3D Printing: Unleashing Complexity and Personalization

In parallel, 3D printing, also known as additive manufacturing, has emerged as a game-changer in the medical device industry. Unlike traditional manufacturing methods that rely on subtractive techniques, 3D printing builds objects layer by layer from digital models. This additive approach allows for unparalleled design freedom, complex geometries, and customization tailored to individual patient anatomy.

Within the realm of stent production, 3D printing offers a paradigm shift by enabling the creation of patient-specific stents. By leveraging advanced imaging techniques such as computed tomography (CT) or magnetic resonance imaging (MRI), clinicians can generate precise 3D models of vascular structures. These models serve as blueprints for designing stents that perfectly match the patient's vascular dimensions, optimizing treatment efficacy and reducing the risk of complications.

Furthermore, 3D printing allows for the use of biodegradable materials in stent fabrication, leading to the development of transient scaffolds that gradually degrade over time. Biodegradable stents offer several advantages, including reduced inflammation, elimination of long-term foreign body presence, and support for natural vessel healing processes. This approach aligns with the concept of personalized medicine, where medical interventions are tailored to individual patient needs, ensuring optimal outcomes and patient satisfaction.

Synergy of Technologies: Hybrid Stents and Advanced Therapeutics

The convergence of electrospinning and 3D printing heralds a new era in stent technology, marked by hybrid stents that combine the strengths of both methodologies. These hybrid stents integrate electrospun nanofibers with 3D-printed frameworks, resulting in multifunctional devices with enhanced mechanical properties, biocompatibility, and therapeutic capabilities.

One notable application of hybrid stents is in the field of drug-eluting stents (DES), which are designed to release drugs locally to prevent restenosis and promote vascular healing. By leveraging electrospinning to embed drug-loaded nanofibers within 3D-printed stent structures, engineers can achieve precise control over drug release kinetics and dosage. This targeted drug delivery approach minimizes systemic exposure, maximizes therapeutic efficacy, and reduces the need for repeat interventions.

Additionally, the synergy of electrospinning and 3D printing enables the development of smart stents equipped with sensors for real-time monitoring of vascular parameters. These sensors can detect changes in blood flow, pressure, or biomarkers, providing valuable feedback to healthcare providers and enabling proactive intervention in case of complications. Smart stents hold immense potential in advancing personalized medicine and improving patient outcomes through continuous remote monitoring and data-driven decision-making.

Future Directions: Towards Advanced Stent Therapeutics and Beyond

Looking ahead, the future of stent technology is poised for further innovation and advancement fueled by electrospinning and 3D printing. Emerging trends include the development of bioresorbable stents that degrade completely over time, eliminating the need for permanent implants and supporting natural tissue regeneration. Bioresorbable stents offer advantages such as reduced long-term risks, improved vascular healing, and enhanced patient comfort.

Moreover, researchers are exploring the integration of regenerative medicine principles into stent design, aiming to create bioactive stents that stimulate tissue repair and regeneration. These regenerative stents may incorporate stem cells, growth factors, or tissue-engineered constructs to promote vascular healing, restore functionality, and prevent recurrent cardiovascular events. The convergence of advanced materials science, biotechnology, and digital manufacturing is driving a paradigm shift towards stent therapeutics that go beyond mere mechanical support to actively promote healing and regeneration.

Conclusion:

In conclusion, electrospinning and 3D printing represent cutting-edge technologies that are reshaping the landscape of next-generation stents. From precision engineering at the nanoscale to personalized customization and therapeutic innovation, these technologies offer unprecedented capabilities in stent design, fabrication, and functionality. The synergistic integration of electrospinning and 3D printing opens doors to hybrid stents, smart stent systems, bioresorbable implants, and regenerative therapeutics, heralding a new era in cardiovascular interventions. As research and development efforts continue to push boundaries and unlock new possibilities, patients stand to benefit from safer, more effective, and patient-centric stent solutions that improve quality of life and redefine standards of care in cardiovascular medicine.